With services such as consulting, modeling, contract research, particle characterization, and testing, PSRI has the tools you need to move your project from your concept to commercialization.

|

Jet Cup Particle Attrition TestingParticle attrition is almost always a detriment to product quality, production cost, and process operability. It is an issue in virtually every solids processing unit operation. Particle size is almost always the most important property governing the behavior of particulate solid necessary. Attrition represents an unintended size change, which can alter the operation or controllability of a particulate process. Therefore, it is extremely important for most processes using particulate solids to measure attrition. PSRI particle attrition can be done in a traditional cylindrical jet cup or in PSRI’s conical jet cup. Testing at ambient conditions in air, at high temperatures (up to 1350˚F or 732˚C) with air, or with nitrogen at low or high temperature is possible. |

|

Particle Size AnalysisA powder or bulk solid’s particle size and size distribution are generally the most important design parameter in particle technology. PSRI has the capability of doing particle size analysis using (i) sieve trays, (ii) electrozone sensing Coulter Counter, and (iii) forward FFT laser diffraction Sympatec. We can sample, riffle, and analyze your material using these instruments. |

|

Minimum Fluidization and Bubbling CurvesUnderstanding the onset of fluidization and bubbling in a fluidized bed is critical in the design, scale up, and operation of commercial fluidized beds. PSRI offers testing of your material at a range of conditions including high temperatures (1350˚F or 730˚C) and pressures (130 psi or 9 bar) and/or with air or nitrogen as fluidizing medium. We also have capability to test at higher pressure, up to 500 psi or 34.5 bar, but price as a project and not a service. |

|

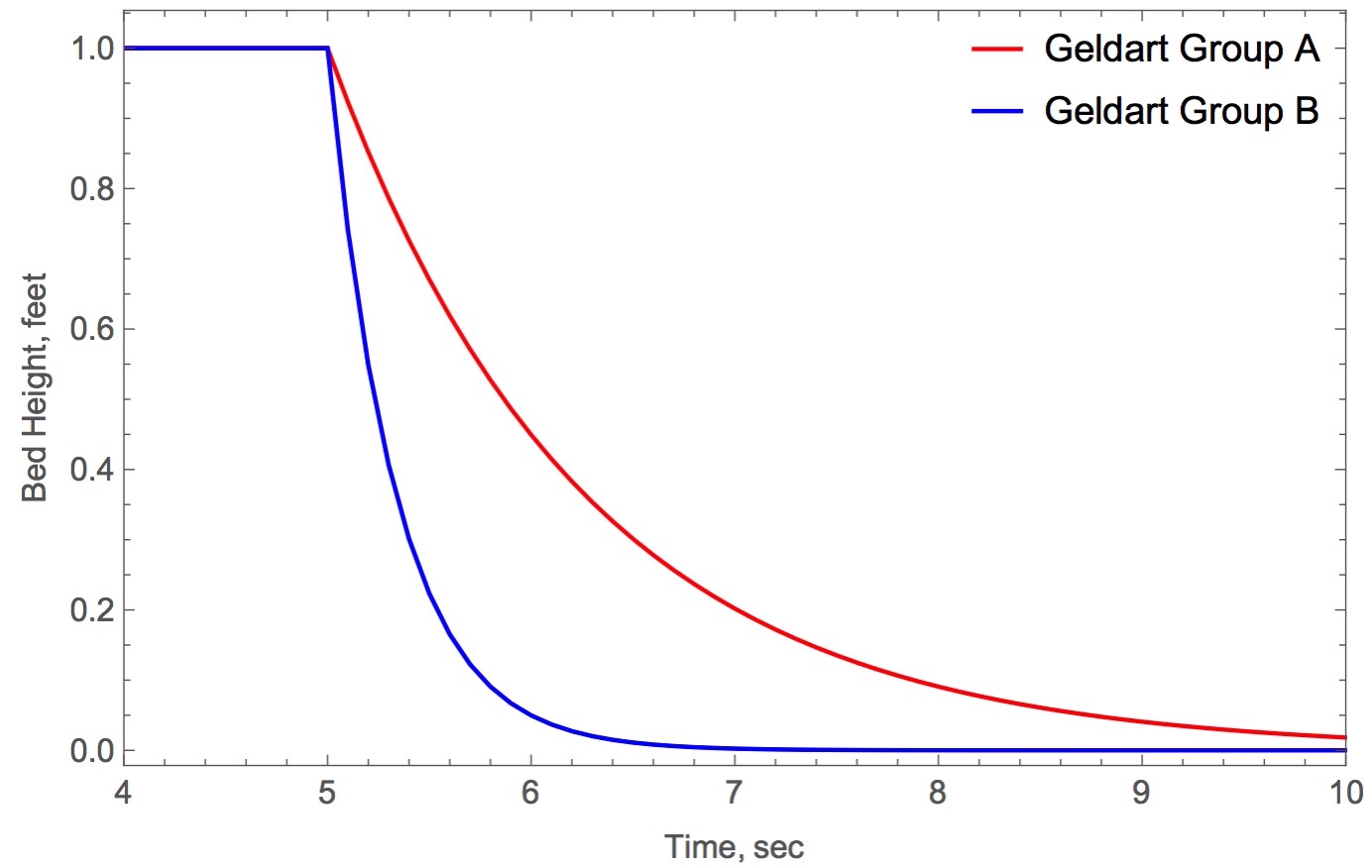

DeaerationDeaeration occurs when fluidizing gas is suddenly stopped. The rate of bed defluidization is often an indication of a materials Geldart particle classification. Fast defluidization is indicative of Geldart Group B material while slow defluidization is indicative of Geldart Group A material. Deaeration time can also be used as a design parameter for many powder handling applications. Deaeration tests can be performed at ambient or high temperature conditions with air or nitrogen as the fluidizing medium. |

|

Permeability CurvesSolids permeability is the ease with which gas can permeate a defluidized bulk solid or powder. It can be an important measurement towards better understanding of how well gas can initially permeate through your solids. Many bulk flow challenges occur due to the inability of gas to permeate a bulk solid during flow. PSRI has the capability to make such measurements both at room conditions and elevated temperatures and pressures with air or nitrogen. |

|

High Temperature Erosion TestingReliability is a key issue with solid-fluid unit operations. Specialized surface refractory is commonly used in the industry to limit erosion and extend operations. PSRI has the capability to test these materials at temperatures of up to 1600˚F (870˚C) for extended periods. Erosion tests are usually conducted with different time durations. |

If you are interested in PSRI’s services, please ContactUS!