- Conducted innovative research on a vortex stabilizer in a secondary cyclone to explain why it is more effective than other configurations (dust hopper, long cone, long barrel) in mitigating secondary cyclone cone erosion

- Developed a design procedure for vortex stabilizers

- Conducted tests on trickle valves and counter-weighted flapper valves to explain why secondary cyclone efficiencies can be so low

- Found that immersing trickle valves and counter-weighted flapper valves shallowly into the tip of the fluidized bed can prevent excessive gas flow up the secondary cyclone dipleg and prevent catalyst losses

- Developed an effective third-stage separator (TSS) for a member company that led to the successful implementation of the TSS into several commercial plants

- Conducted extensive testing on bypassing to determine why it occurs, what parameters influence it and how it can be mitigated

- Demonstrated how the gas bypassing in the fluidized bed could result in poor performance of primary cyclone dipleg leading to flooding

- PSRI has been a leader in studying and optimizing standpipe operation/standpipe entrance configurations and aeration amount and location

- PSRI has developed correlations to determine the optimum amount of aeration to add to a standpipe

- Developed a bypass line (called a burp tube) for hybrid-angled standpipes to allow gas collecting at an elbow to be bypassed from the elbow into the freeboard of the fluidized bed above it

- PSRI has been one of the first to characterize the radial gas and solids distribution in risers

- Improved the design of the transition between a mixing pot and the riser above it

- Studied different riser exit configurations with respect to erosion, pressure drop and how much attrition is produced at each configuration

- Developed design procedures for gas distributors

- Studied and evaluated several close-coupled cyclone designs

|

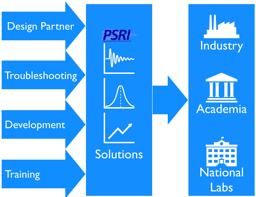

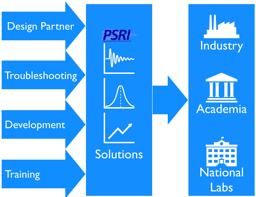

PSRI ConsultingPSRI has over 160 years of experience and over 225 reviewed publications in fluidization and particle technology |

Fluidized Catalytic Cracking (FCC)

|

Contact PSRI our Consulting Team today to help with your project!Click Here to contact via web or call us at +1-773-523-7227 |

©

1971 - 2023

Particulate Solid Research, Inc

PSRI Restricted: Authorized Access Only