- Developed technology specifications to design gas distributors, catalyst injection system, expanded bulb, etc

- Conducted cold flow testing at high pressures to identify the parameters that affect the electrostatics in the fluidized bed reactor leading to sheeting, developed instrumentation to measure the levels of static electricity

- Designed cyclone system for gas-phase and condense-phase polyolefin reactors

- Assisted in developing a reliable angled eductors to feed the collected fines back to the reactor

- Designed dense-phase conveying system for product transfer and at the same time depressurize the polyethylene

- Design and assess proper design polymer purge bins to insure limited volatile organic compound content and proper polymer residence time distribution during various modes of operation

- Bin, hopper, feeder, and valve design and selection for storage and transportation of polymeric materials

- Identified the source for producing angel hair during the conveying of resin

- Developed catalyst process that provides optimum particle size distribution

- Developed catalyst injection system that minimize catalyst attrition

- R. Hays, S. Karri, R. Cocco, T. Knowton, Small Particles Cluster Formation in Fluidized Beds and its Effect on Entrainment, Circulating Fluidized Bed 9. 9 (2008) 1–5.

- M. Guedon, T. Baron, C. Briens, T. Knowlton, Intermittent Injection of Prepolymer in a Pressurized Fluidized-Bed, 78 (1994) 25–32.

- D. Benoni, C. Briens, T. Baron, E. Duchesne, T. Knowlton, A procedure to determine particle agglomeration in a fluidized bed and its effect on entrainment, 78 (1994) 33–42.

- C. Briens, M. Guedon, T. Baron, T. Knowlton, Intermittent Discharge of Powder from a Pressurized Fluidized-Bed of Polyethylene Powder, 78 (1994) 43–50.

- F. Shaffer, B. Gopalan, R.W. Breault, R. Cocco, S.B.R. Karri, R. Hays, et al., High speed imaging of particle flow fields in CFB risers, (2013) 1–14.

|

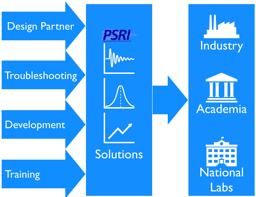

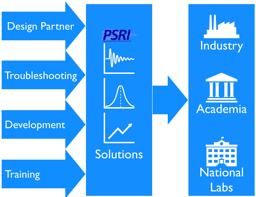

PSRI ConsultingPSRI has over 160 years of experience and over 225 reviewed publications in fluidization and particle technology |

Polyolefin Process

|

Contact PSRI our Consulting Team today to help with your project!Click Here to contact via web or call us at +1-773-523-7227 |

©

1971 - 2023

Particulate Solid Research, Inc

PSRI Restricted: Authorized Access Only