- Developed technology specifications to design gas distributors, expanded bulb, etc for the reactor

- Conducted cold flow testing t high pressures to identify the parameters that affect the fluidization characteristics and entrainment issues

- Determined optimum particle size distribution for the FBR

- Designed cyclone-dipleg system for this application.

- Demonstrated a technology to continuously purge out solids from the dipleg to prevent building up of impurities in the reactor

- Assisted in developing a reliable angled eductors to feed the collected fines back to the reactor

- Selection of particle feed size distribution to achieve optimal reactant conversion, particle gas contacting, stable hydrodynamics, limited unreacted solids losses

- Management of solids entrainment in high pressure, high temperature, corrosive environments with dynamically evolving particle size distribution

- Conceptual understanding of the link between feed impurities, particle cohesion, and the resulting reactor hydrodynamics and operability

- Assisted in operating both pilot and commercial reactors in a reliable fashion

|

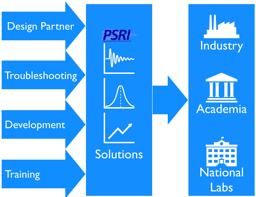

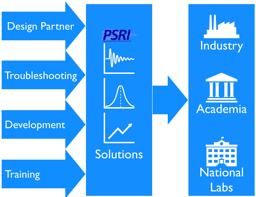

PSRI ConsultingPSRI has over 160 years of experience and over 225 reviewed publications in fluidization and particle technology |

Polycrystalline Silicon

|

Contact PSRI our Consulting Team today to help with your project!Click Here to contact via web or call us at +1-773-523-7227 |

©

1971 - 2023

Particulate Solid Research, Inc

PSRI Restricted: Authorized Access Only