- Developed new reactor designs and new conical reactor distributors for a client

- Designed and developed L-valve feeding systems for TiO2 ores and coke for two PSRI member companies

- Designed a Restricted Pipe Discharge System (RPDS) to continuously discharge solids from a chlorinator bed to prevent excessive buildup of impurities

- Determined minimum gas velocities to prevent segregation of ore and char were for plant turndowns

- Demonstrated distributor design to minimize refractory erosion

- Designed spargers, grid plates and heat transfer tubes ethylene chlorination

- Minimize catalyst attrition with redesign of nozzles, spargers and cyclones

- Reduced cyclone and dipleg erosion with new cyclone design

- Assisted in the design of a novel direct ethane chlorination process

- Developed in-situ probe for quantification of bed hydrodynamics in chlorination unit

- Troubleshoot refractory issues in oxychlorination units

|

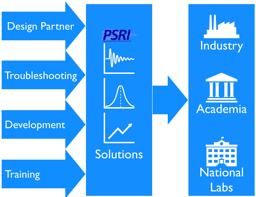

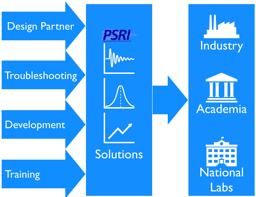

PSRI ConsultingPSRI has over 160 years of experience and over 225 reviewed publications in fluidization and particle technology |

Chlorinators and Oxychlorinators (TiO2 & PVC)

|

Contact PSRI our Consulting Team today to help with your project!Click Here to contact via web or call us at +1-773-523-7227 |

©

1971 - 2023

Particulate Solid Research, Inc

PSRI Restricted: Authorized Access Only