Background

PSRI had conducted a long term research program to identify the major sources of particle attrition in both fluid bed and circulating fluid bed systems. In fluid beds, the major sources of particle attrition are identified as both submerged high velocity gas jets at grids and the first stage cyclone inlet region where the entrained solids are subjected to high centrifugal force which results in high impact across the inlet duct on the barrel wall. In addition to these two sources of attrition, the attrition in bends is another important source for circulating fluid beds.

Program Objectives

The objectives of the current particle attrition and erosion program are outlined below:

Attrition:

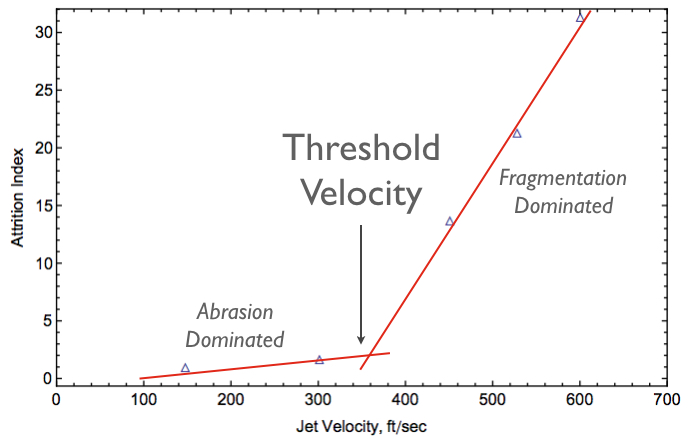

- Conduct testing in PSRI conical jet cup to understand the effects of inventory, jet velocities, time on stream, particle densities and particle size distributions.

2. Conduct selective 12-in-diameter fluidized bed testing to measure the combined steady state attrition rate due to the grid and primary cyclone attrition and validate the attrition models.

3. Conduct selective 36-in-diameter fluidized bed testing to measure the combined steady state attrition rate due to the grid and primary cyclone attrition and validate the attrition models (scale-up).

4. Conduct a limited number of tests in circulating fluid beds to determine the combined steady state attrition due to all three sources: grid, riser termination (bend), and 1st stage cyclone and validate the all three models.

5. In addition, attempts will be made to develop a correlation between the attrition index from conical jet cup testing and attrition rate constants in the rate models.

6. Benchmark Comparison: Predict the steady state attrition rate of catalyst particles (catalyst losses) in a commercial fluid bed reactor or a given refinery using the validated attrition rate correlations. Need controlled data from a member company.

7. Development and validation of population models .

Erosion:

-

Conduct testing in hot erosion test rig to understand the relative erosion characteristics of various stainless steel type (304, 310, Incoloy® alloy 825, Stellite 6), carbon steel type and various refractory linings, etc. Tests can be conducted at high temperatures up to 1300 oF.

-

Benchmark PSRI erosion test results vs. ASTM C704M-12 technique for their relative erosion indices of several refractory coupons .